the shape of the indenter in brinell hardness test is|brinell hardness chart pdf : distributors Brinell Testing (BHN) Brinell was a Swedish engineer who developed this testing process to determine both hardness and tensile strength. It consists of indenting the surface of the metal . 15 de nov. de 2023 · 1) Management KPI Dashboard. Our first data dashboard template is a management dashboard. It is a good example of a “higher level” dashboard for a C-level executive. You’ll notice that this .

{plog:ftitle_list}

Resultado da 23 de fev. de 2024 · Confira as 10 criptomoedas mais promissoras para 2024. O time de análise ( research) do MB listou as 10 moedas digitais mais promissoras para 2024, oferecendo aos investidores uma valiosa perspectiva. No entanto, é crucial reconhecer que prever com precisão o desempenho .

In the Brinell hardness test, an optical method, the size of indentation left by the indenter is measured. In contrast to the optical Vickers method, in which a pyramid-shaped indenter is pressed into a specimen, the Brinell method uses .A Brinell hardness result measures the permanent width of indentation produced by a carbide indenter applied to a test specimen at a given load, for a given length of time.Indenter shape and material: The indenter is a tungsten carbide metal ball, with a diameter of 1, 2.5, 5 or 10 mm, depending upon the specific Brinell method. Brinell test procedure. In the .The Rockwell hardness test uses a diamond cone or steel ball indenter to make an indentation in the material being tested. The depth of the indentation is measured and used to calculate the Rockwell hardness number (RHN) of the .

Brinell Testing (BHN) Brinell was a Swedish engineer who developed this testing process to determine both hardness and tensile strength. It consists of indenting the surface of the metal .The typical test uses a 10 mm (0.39 in) diameter steel ball as an indenter with a 3,000 kgf (29.42 kN; 6,614 lbf) force. For softer materials, a smaller force is used; for harder materials, a tungsten carbide ball is substituted for the steel ball.An alternative method is the Brinell hardness test, which uses a hardened steel (or tungsten carbide) ball indenter with a diameter D of, usually, 10 mm. This is applied under a load P of .As the Brinell hardness test (HBW) indentation leaves a relatively large impression, the Brinell hardness test is better suited to larger samples with a coarse or inhomogeneous grain structure, such as castings and forgings. .

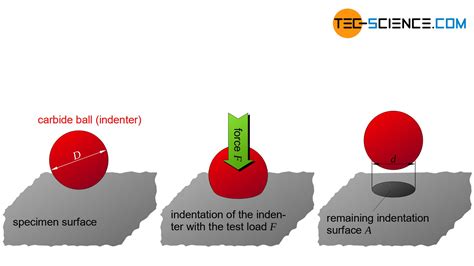

The general principle of the Brinell indentation hardness test consists of two steps: The indenter is brought into contact with the test specimen in a direction perpendicular to the .Further details on the Brinell hardness test, especially concerning precautions to be taken while carrying out the test, can be obtained from ASTM standards E10 (1984). . Two indenter shapes are employed. The Vickers indenter is a square-based pyramid with face angles of 136°. The lengths of the two diagonals of the resulting square indent .Hardness tests can be defined as forcing an hardness testing indenter of a specified size, shape, and material into the surface of a test piece to obtain a hardness value. Skip to content +1 847-295-6500 Applications of Brinell Hardness Test: The Brinell hardness test is defined in ASTM E10 is used to calculate Brinell hardness of the metal. It is used on the metal having a rough surface and harsh texture. The Brinell .

With the Brinell hardness test, a carbide ball is pressed into the material. The indentation surface serves as a measure of the hardness! . An indenter (e.g. ball, cone, pyramid, etc.) is pressed with a certain force into the material surface to be tested. The indentation hardness value is determined from the indentation left behind. An indenter with specific shape for each method is brought into contact with the material to be tested; then apply a specific test force to the indenter until the indenter makes a permanent deformation in the tested material. . Brinell hardness test- Verification and calibration of testing machine. Google Scholar ISO 6506-3 (2014) Metallic .

For example, it is fairly common when measuring the hardness of an armour casting to use a Brinell hardness test because the indenter is a ball. Remember that the surface of a casting can be fairly irregular and the substrate is likely to be heterogeneous in nature. . The diamond indenter used are in shape of a pyramid and the indentation .Indentation is the essential phase of various non-cutting methods for determining the hardness of a material. The Brinell hardness test uses a small ball of steel or tungsten carbide to cause the .It is an optical method. This means that the size of indentation left by the indenter is measured to determine the hardness value of a test specimen. Indenter shape and material: The indenter is a tungsten carbide metal ball, with a diameter of 1, 2.5, 5 or 10 mm, depending upon the specific Brinell method.A Vickers hardness tester. The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. [1] The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter .

Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion .Brinell Hardness Test Rockwell Hardness Test; Indenter Shape: Spherical: Diamond cone or steel ball: Load Applied: High (500 to 3000 kg) . The spherical indenter used in the Brinell hardness test can accommodate variations in the surface of the material being tested. This makes it suitable for testing materials with rough or irregular surfaces.Hardness Methods: The Rockwell hardness test measures the depth of penetra-tion of an indenter into a material under a known load. It provides a hardness value based on the depth of penetration. Rockwell Hardness The Brinell hardness test involves indenting a material with a hard sphere under a specific load. Two diameters (x and y

A Brinell hardness testing machine that is designed to be transported, carried, set up, and operated by the users, and that measures Brinell hardness by the Brinell indentation hardness test principle. Brinell hardness machine. Equipment for Brinell hard- ness testing usually consists of a testing machine, which supports the test specimen and .Rockwell hardness (HR) is a valuable and widely used indentation hardness test for evaluating mechanical properties of metallic materials. For the Rockwell scales that use a ball indenter, either a steel or tungsten carbide (WC) ball indenter is permitted to be used in the test method standards of ASTM International and International Organization for Standardization (ISO). Recent international comparisons of primary standards of Rockwell C hardness showed that the indenter shape is largely responsible for differences in measurement results.

After the preliminary test force has been applied for a short time, the dial gauge is set to zero (reference level). The actual hardness value can then be determined. Figure: Rockwell hardness test procedure. The actual .Brinell Hardness Testing . The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and understand the standard completely .According to the latest standards, there are changes to both Rockwell and Brinell scales. The test method for Rockwell testing (ASTM E-18-08a) only allows the use of tungsten carbide ball indenters.Metals hardness testing is the measure of how resistant a solid matter is to permanent shape change when an indenter is applied at a known force. When testing metals, the indentation hardness correlates linearly with the tensile strength of the material. . Brinell Hardness Test Blocks — ASTM E-10 and ISO 6506. All of our Brinell Test Blocks .

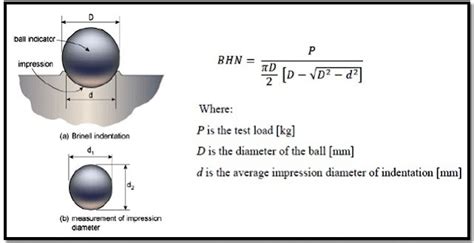

laboratory charge analyzer

The Vickers Hardness test (ISO 6507) is used to characterize hardness of various solid materials (metals, ceramics, etc.). . In contrast with Rockwell and Brinnell hardness techniques, the pyramid indenter is advantageous since the square imprints are easier to measure than the round impressions from spherical and conical indenters . On completion of the Brinell test, the hardness number is calculated as follows:, where. F – force, N. D – indenter diameter, mm. d – indentation diameter, mm . Rockwell Hardness Test. . The diamond indenter is in the shape of a four-sided pyramid. After touching the part, the machine soon reaches the pre-determined force value. .The shape and size of the indenter differs between the most common methods, but the general principle is to apply a known force to an indenter of a given shape onto the material's surface. The size of the indentation that is left is then related to a measurement of hardness. . An alternative method is the Brinell hardness test, which uses a .

Brinell Hardness Tester holds significant importance in today's industrial landscape, where understanding material properties is crucial for ensuring product quality, reliability, and performance. This test reveals vital information about their hardness, toughness, and suitability for specific applications by subjecting materials to controlled indentation.2. Brinell Hardness Test. The Brinell test uses a larger spherical indenter, usually made of steel or carbide, and applies a heavy load to the material. The diameter of the indentation is measured to calculate the Brinell hardness number (HB). This method is ideal for testing softer or larger materials like cast iron and steel.

The Brinell hardness (BH) test measures the hardness of rock (kg/mm2) based on the displacement of a steel ball penetrating into a core sample exposed to a fluid over a certain period. . A wide range of materials can be tested using a Brinell test simply by varying the test load and indenter ball size. In the United States, Brinell testing is .In the Rockwell hardness test, a differential-depth method, the residual depth of the indent made by the indenter, is measured.In contrast, the size of the indentation is measured in the Brinell, Vickers and Knoop optical test methods.. The deeper a defined indenter penetrates the surface of a specimen with a specified test load, the softer the material that is being tested.The type of indenter and the test load determine the hardness scale(A, B, C, etc). . 3.2. Brinell Hardness Test. . The diamond indenter employed in the Knoop test is in the shape of an elongated four-sided pyramid, with the angle between two of the opposite faces being approximately 170º and the angle between the other two being 130º. .

what is a brinell hardness

how to measure brinell hardness

brinell hardness testing error

WEB4,559 likes, 50 comments - milkyperu.official on September 6, 2023: "@vitoriabeatrizlives 🇧🇷mais grande do mundo🤩 #model #brasil #newpost #fyp"

the shape of the indenter in brinell hardness test is|brinell hardness chart pdf